| We will

now return to the E-Type Series 1 3.8, but most of these comments also

apply to XK 150 and the various Marks.

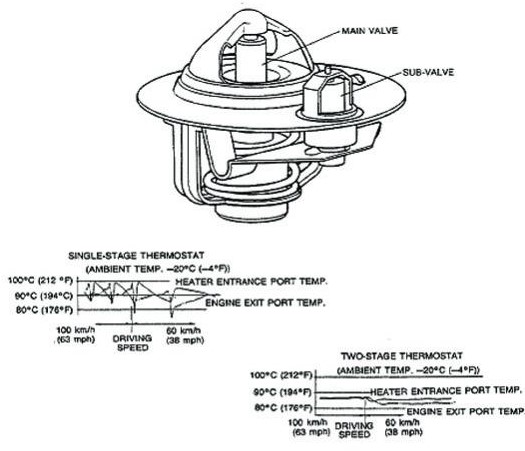

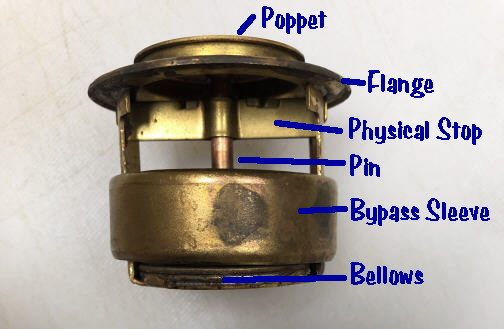

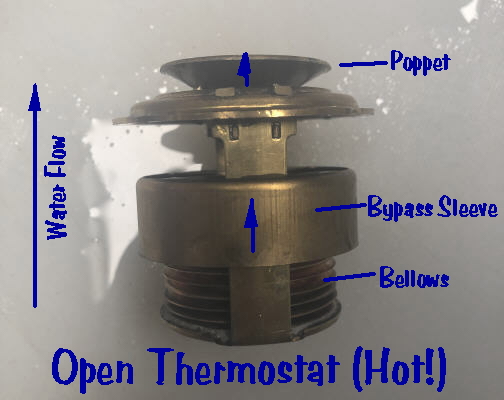

The best British thermostat in 1960 was the Smith sleeved bellows style, although it was already an anachronism. As we have seen, bellows thermostats constrain cooling system design because they are intolerant of high ambient pressure, and the resulting 3.8 cooling system reflects these limitations. Let's take a closer look.

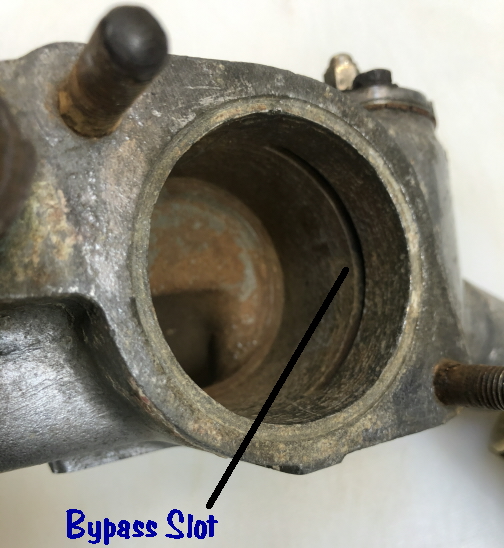

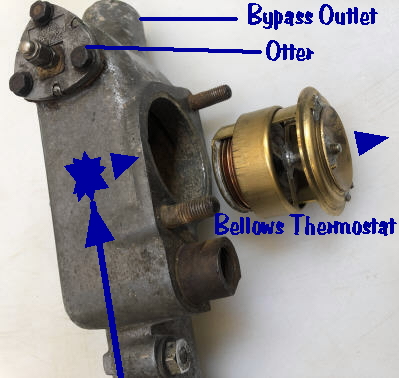

Water

exits the 3.8 engine block through the intake manifolds, then up through

a separate water rail. The thermostat housing sits at the front of the

water rail, at right angles to the primary flow path. While the engine

is cool, bypass flow exits the thermostat housing through a slot cut into

the side of the passage, and then out through the front of the rail. When

the bellows expands, the control sleeve moves forward with the poppet,

and will cover the bypass slot, while opening the main passage to the radiator

:

By forcing

the main flow into a right angle turn at the base of the thermostat, dynamic

pressure is less likely to lift the poppet. But blunting the flow at this

point raises static pressure locally, which affects the expansion of the

bellows. For this reason, a 4 lb pressure cap is the maximum that can be

used. This is a fundamental compromise to the efficiency of the cooling

system.

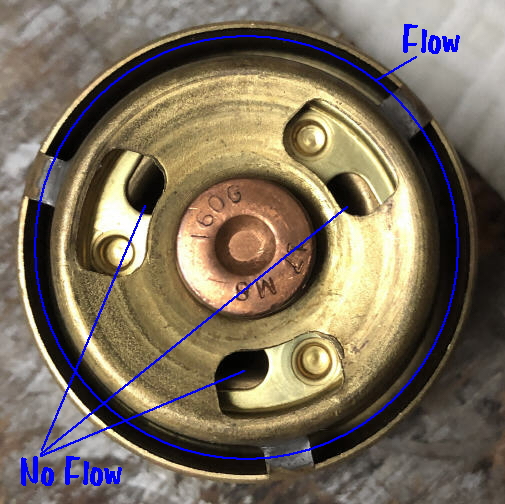

So what thermostat can be used with this system today? Here are some options: 1) The original Smith's thermostat is 85025 is the easy choice, if you can locate an example. In most cases, the summer temperature range, 74 or 75C is the best choice. As the supply of these is gradually exhausted, there are reasonably good repros of the Smith style bellows thermostat available from Moss (PN 434-156) or Rimmer Brothers (pn 107590). The only available temperature range for these is 74C. The approximate flow cross section for all bellows thermostats is .75 sq", which is relatively restrictive. The sleeve diameter on an original Smiths is 48.3mm, the Moss sleeve is 48.1mm. Because maximum system pressure is 4lbs with a bellows thermostat, you must always use a 50/50 or stronger solution of antifreeze to get adequate boiling point elevation. Boiling Point Elevation vs Pressure

Bellows thermostats limit the design because they are sensitive to pressure. Since a wax motor thermostat allows for higher pressures, and thereby extends boilover protection, let's look at some options that will allow you to use a higher rated cap. 2) Best

alternative solution. If you are very lucky, you may be able to find Jaguar

pn c20766 or c20766/1 (175F or 182F). This was the original wax thermostat

designed as a retrofit for Smiths 85025. Flow cross section is exactly

1 sq inch. Since it has a wax motor, the pressure rating of the cap can

be increased to elevate boiling point. This thermostat was specified as

a drop-in retrofit for the 3.8 E-Type. It was factory installed after 1962

on all S1 3.8's and 4.2's. Sleeve diameter flares from cap to leading edge,

and is 48.4mm at the leading edge. Perfect. Factory. Unobtainable. I have

no idea why Jaguar would have let this go out of production, as it's applicable

to all sleeve-bypass applications. This thermostat must have disappeared

fairly early after the introduction of the 4.2 engines, as not one of the

cars and scrap manifolds I've examined still has one. All of them had single-poppet

thermostats (see below), with no bypass provision whatsoever.

3) Alternative: Several vendors supply a thermostat, C3731/1. This is a cut down Land Rover Series IIa thermostat (see below), which mimics the reverse action of c20766. It fits without modification. The flow cross section of 3731/1 as well as the source Land Rover thermostats is .94 sq in. Unfortunately, when the Land Rover's tapered bypass shutter is cut down, it ends up being just over 47mm diameter, leaving a gap of 1.25mm at the bypass. Adding to this, the part seems to have gone through some evolution and so the spec is inconsistent from example to example. Opening temperature is 74c. 4) Alternative: unmodified Land Rover Series IIa thermostat. The original LR thermostat is a cousin to Jaguar c20766. The diameter of the full bypass shutter is 48.5mm., however, on the widely available Chinese copies, the shutter is often just 47.5mm. Unfortunately, the LR thermostat will not fit in a 3.8 housing unless the car's thermostat neck is modified. It needs to be bored out to 54 mm for a depth of 9mm. Once the neck is machined, it will ONLY accommodate a Land Rover thermostat, so it's a permanent commitment. Here

is a photo comparison of Jaguar C20766, the Land Rover SIIa thermostat

and c3171/1, open and closed. Note the conic section sleeves on the original

Western Thomson thermostats. When the sleeve is cut down for 3171/1, the

diameter is reduced:

5) Workable

solution. Use a non-bypass wax thermostat. At some point, Jaguar superseded

C20766 with C27650, which is a 74C, single poppet thermostat. Flow section

of the original part is .81. This thermostat is still available under this

part number, but the specific design has changed over time. Although the

thermostat will not control the bypass passage, most of the flow will still

pass through the main poppet. This would be similar to the open bypass

application described in Chapter 3. Unfortunately, the right angle turn

made by flow at the thermostat housing will encourage bypass flow.

6) A

possible improvement when using a single poppet thermostat would be to

completely block the bypass using a brass stopper in the hose, and then

drill a 3/8" hole in the flange, or use Stewart Components model 300 or

301, which are Robertshaws which have been punctured to allow some bypass

flow through the radiator. (Warning: there have been reports of freeze

plugs popping if the holes in the thermostat aren't large enough.) A modest

leak in the thermostat would cause somewhat longer warm ups, but nobody

is driving these cars in the winter. The Robertshaw thermostat is a high

flowing thermostat in its native application, and even with the constraint

of the 49.6mm thermostat housing in a Jag, it will have an effective flow

cross section of 1.09 sq in.

7) Finally, a decent modern solution that's gone NLA. Several vendors once offered a modified Robertshaw thermostat for this application. Because the sleeve of the Robertshaw is just 40mm, a secondary 49mm sleeve was soldered to the thermostat using brass tabs. This further constrained the flow path to about .75 sq in, which is comparable to the original Smiths. The set point was either 71C or 76C, depending on the choice of donor thermostat. The wide sleeve did a good job of blocking the bypass when open. Unfortunately, not in current production.

Things to know. - Fail safe thermostats. Not appropriate for this application. This design has a spring loaded clip that locks the thermostat open if the temperature exceeds some predefined limit, usually 230F. The theory is that at these elevated temperatures, the thermostat will fail and collapse, permanently closed. But locking it open has no value. If you reach these temperatures, you will know it, and you should replace the thermostat as a matter of good practice. The wax motor will only fail if the temperature exceeds the melting point of the rubber seal, which won't happen unless the fluid is completely boiled out. At that point, it may or may not collapse. More likely it would stick at some mid point. While nominal risk is small, the true risk with fail safe designs is that the thermostat may lock without you knowing, in which case the thermostat would be inoperative and warm up will be extended. And none of the available fail-safes have bypass control sleeves. - SuperStat.

SuperStat is a trademark of Stant. Buyer beware: there are no SuperStats

that have a bypass sleeve for S1 E-Types. The label appears on Stant or

Gates thermostats with a weir valve design, and cannot be properly attached

to any other product. A weir valve is a short cylinder welded or pressed

into the flat poppet. The cylinder has a series of deep V-shaped notches.

The idea is that instead of exposing flow along the entire periphery of

the poppet, coolant will initially only flow through the apex of the V

notches. This gives more precise, gradual control at start-of-open, and

so tighter thermal regulation. Only when the thermostat has opened a good

part of the way will the periphery open up to maximize flow, giving a non

linear response to rising temperature.

<Bypass

Systems Main

S1 E-Type 4.2>

Copyright©2019

CoolCat Express Corp

|

`

`